Compressed Air: Smart Point-of-Use Systems Bring Energy and Cost Savings

Over time, there have been technological advances in preparing air for use before it enters machines for operation. Advancement was slow until we learned more about how to implement digitalization.

For a basic air system, the compressor room has a compressor, an air dryer to remove water or moisture from the air, and mainline filtration to remove particulates and compressor oils. When leaving the compressor room, the air piping will be plumbed to the point of use, including machines such as case packers or case erectors. Those are just two of many machine types that use pneumatic automation for numerous functions.

For many machines, at the point of use, a filter regulator and lubricator unit (FRL) is installed. The FRL is usually connected in a compact package and further regulates the air pressure and removes contaminants before the air is finally used in the machine. In the case of lubricators, few applications will require these and may be left off the system.

Pneumatic control is a natural place to look for energy savings and sustainability opportunities. Detecting or predicting component failure in a pneumatic system is also possible if the right data is analyzed.

Since all of the air at the machine point of use flows through the FRL, it is the ideal place to add flow, temperature, and pressure sensors for predictive maintenance analysis and energy savings opportunities. Pneumatic component manufacturers have realized this and developed products with remarkable success in energy reduction and overall cost savings for end users’ facilities. Many of these products are designed to be an integral part of an FRL or may be used as a stand-alone unit.

How Digitalization Can Benefit

Smart point-of-use air management systems contain high-level features that can help a facility reduce costs. Energy consumption can be reduced by leveraging the unit’s digitized data, leak reduction methods and predictive maintenance capabilities.

The addition of digitalization has allowed onboard sensors to gather data, which is then sent to a hub installed on the unit. This data utilizes OPC Unified Architecture (UA) to communicate flow, temperature and pressure measurements used to establish baseline conditions for machines and other air consumers. This data is valuable for sustainability and predictive maintenance.

READ MORE: Understanding Digitalization and its Use in Fluid Power

Achieving Energy Cost Reductions

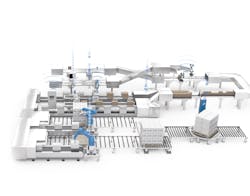

The primary areas to decrease energy and associated costs are air leak reduction and lessening internal leakage of system components such as cylinders and valves. The idea is to reduce pressure or completely shut off the air supply during machine idle times. Manufacturers install flow, pressure and temperature sensors, pressure regulators and shut-off valves at the machine point of use to measure and ultimately control airflow and pressure to a machine—saving costs (Figure 1).

With the digitized data collected, these sensors detect user-defined idle times during a machine cycle and automatically reduce the pressure controlled by an electropneumatic air regulator. During long-term idle times, a two-way valve is used to completely isolate airflow to a machine.

As machines are idle at maximum pressure during non-production or minor stoppages, the inherent amount of leakage due to line or connector loss or internal component leakage can be high. Parameters can be set in the point-of-use air managment system to detect idle time and programmed to reduce air pressure for a period of time called standby mode. Reducing the air pressure decreases the potential for leakage and wasted air during these idle times, therefore reducing the CO2 emissions related to lessened compressor load.

The unit enters isolation mode during prolonged inactivity, triggering the two-way valve and ultimately stopping airflow altogether. These long-term idle times can be programmed for weekends and seasonal, planned, or unplanned downtime. These periods can also be relatively short, like when a machine stops for only a few minutes.

Note that during standby mode, pressure is reduced but not completely shut off. Therefore, air will remain in the system. When returning from standby mode into normal operation, ramping back up to pressure takes less time than it would in complete isolation mode, with the air pressure entirely exhausted from the system.

READ MORE: Uptime and Energy Efficiency to Drive Fluid Power Market in 2023

Condition-Based Predictive Maintenance

The pressure, flow and temperature sensors can also set a baseline within the onboard data hub. During normal operation over time, a digital fingerprint is established, and the data can determine and flag anomalies to reveal potential problems before a system component fails.

For example, it can detect excessive air consumption during a period of machine cycling. This could indicate a potential air leak due to worn seals in a cylinder, and the early detection would allow for cylinder replacement during scheduled downtime—which would be another cost saving.

Scalable Architecture

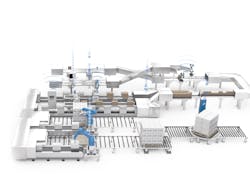

In some cases, manufacturers have installed wireless technology that enables smart air management systems to communicate with each other (Figure 2). For example, one base unit will communicate with 10 remote units installed on other machines. All information is taken from these remote units, funneled to the base unit, and reported upstream into the network. The factory network can then connect to a gateway and then the cloud. This allows for only one data hub connected to the factory network. Units can also be hardwired through a fieldbus network instead of using the wireless method if desired.

Installing smart point-of-use air management systems is a great way to implement cost-saving solutions in a facility, particularly where several machines are operating, and the potential is high for internal/external leaks and component failure. In their simplest form, these units can operate without being integrated into the plant network and use only the onboard interface.

The installation cost is low, and the unit will have a quick return on investment. In their more complex form, these units integrate into the facility network and implement a data analysis method. The potential savings from this option will be even greater, resulting in an even shorter payback period.

This article was written and contributed by Alan McCay, CFPS, Motion.

About the Author

Alan McCay

Eastern U.S. and Canada Group Fluid Power Director, Motion

Alan McCay, CFPS, has worked for Motion for over 25 years and is currently Eastern U.S. and Canada Group Fluid Power Director. For more information, visit Motion.com.

Leaders relevant to this article: