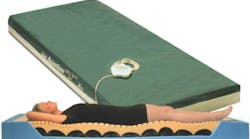

Hospitalized and infirm patients confined to bed are prone to pressure ulcers and bed sores. They’re caused by pressure on the skin at weight-bearing, bony points such as hips, heels, and elbows. One way to prevent or help heal pressure ulcers in immobilized people is with alternating air-pressure mattresses.

These dynamic-pressure mattresses contain plastic air cells that alternately inflate and deflate to relieve pressure on the body. Inflation and deflation cycles change pressure on the skin in a controlled manner and the rate can be tailored to the individual patient. Pressure mattresses also improve comfort and can aid in repositioning bed-ridden patients.

Span-America Medical Systems, Greenville, S.C., manufactures several versions of these “intelligent” mattress systems. For instance, its PressureGuard Turn Select model incorporates a microprocessorcontrolled pneumatic motion system built into the mattress that laterally rotates the patient. Air tubes inside the mattress run the length of the bed. By selectively inflating one side and deflating the other, caregivers can create customized motion patterns that roll the patient left and right at angles up to 30°, and with dwell times of 1 to 120 minutes in any position. Another version, the PressureGuard Site Select, adjusts pressure at specific body points, instead of turning the patient.

In designing the units, the company had stringent requirements for the pneumatic system, explains Rick Raburn, an engineer with Span-America. For instance, the valve manifold system had to provide adequate airflow to quickly fill the urethane bladders, consume little power, minimize leakage, and mount into the tight confines of the electronic control box with a nonstandard bolt-hole pattern.

To meet these requirements, the company turned to Humphrey Products Co., Kalamazoo, Mich. Its Engineered Solutions group, experienced in the design and development of special products, recommended 310 Series valves mounted on a custom manifold.

The 310 Series valves are /8-in. port, 3-way, 2-position valves with a single solenoid and spring return. They are suited for use with compressed air or inert gas at pressures from 0 to 125 psig and vacuum service to 28 in. Hg, and have a flow rate of 0.10 CV. The valves are prelubed and can operate without lubricated air for approximately 20 million cycles –– far beyond the expected life of the bed.

A significant feature is the ability to set up the same basic manifold to produce different outputs, based on design requirements.

“We configure the manifold two different ways for the TurnSelect and Si teSelect ,” notes Raburn. “The difference is the TurnSelect has four tubes that run from head to foot, and the SiteSelect has tubes that run across the mattress –– three tubes per zone and four zones,” so airflow requirements are a bit different for each.

“Simply changing plugs in the manifold changes the internal pneumatic circuitry. This lets the same manifold be used on the two different mattresses,” says Mike Craig, Humphrey’s engineering project manager. For one, the manifold supplies vacuum to three valves and pressure to two valves, expla ins Craig. “One pressure and one vacuum valve work as a set controlling the pressure in two sets of bladders within the mattress. The fifth valve acts as an exhaust valve to atmosphere for the entire system,” he says.

In the second circuit, four valves supply four individual bladders within the mattress. The fifth valve acts as either a total mattress exhaust or, by turning specific valves on or off, as an exhaust for a specific bladder within the mattress, says Craig. Air and vacuum supplied to the manifold are about 7.0 psi and 14 in. Hg, respectively.

Potential leakage was a concern to avoid deflation in the event of a power loss. And low leak rates mean the compressor is not constantly running to replace lost air, making for a more-efficient system.

Combining the valving on a onepiece of manifold, instead of using separate, standalone valves, eliminates many interconnections that are potential leak points, say Craig. Also, the 310 Series valves have an elastomeric-poppet design. These have better sealing characteristics and minimal leakage, compared to spool valves. Finally, pipe ports with straight threads using fittings with tapered threads provide tight, point-of-contact sealing, he says. The design easily met Span- America’s leak-rate requirements of <4 cc/min.

The 310’s balanced-poppet design also requires little force to actuate, and thus the valve consumes little current, adds Craig.

The custom valve manifold is sized to fit into the control box and includes ports and bolt holes configured to customer specifications. Every unit is pretested prior to delivery, and they’re supplied with electrical connectors to speed installation and reduce assembly costs. As an added benefit, the system runs quietly and generates little heat, increasing patient comfort.

For more information, contact Humphrey Products Co., Kalamazoo, Mich. 49048, (269) 381-5500, www.humphreyproducts.com, and Span-America Medical Systems, P.O. Box 5231. Greenville, S. C. 29606, (864) 288- 8877, www.spanamerica.com.

|

Some thoughts on leakage But that doesn’t imply that spooland- sleeve designs are inherently bad. It is true that a spool-and-sleeve construction valve will have as much as four times the air travel across a land as a bubble-tight style valve. However, it is important to understand what that air movement means. In a spool-and-sleeve valve, the thin film of air that travels across the lands (whether the valve is shifted or not) serves a purpose, and as such should not be referred to as leakage — it is consumption. Air travel in a lapped spool-and-sleeve valve supports the air-bearing effect that prevents metal-to-metal contact. This frictionless fit is the secret to billions of cycles, compared with tens of millions, or less, for dynamic seal valves. Many spool-and-sleeve valves installed in the 1950s are still running trouble-free today in their original applications. Dynamic seal valves do eventually leak when stationary, especially after they have worn. The term bubble tight is often used to describe the leakage rate of dynamic seal components. A common misconception is that bubble tight equals zero leakage. This is not true — bubble tight only means there is so little leakage that a bubble of air does not break away when a product is cycled for a minute, submerged in a tank of water. A device can leak as much as 50 cc/ min and still be considered bubble tight. Further environmental conditions such as temperature, humidity, and lubrication all affect the wear and, thus, the leakage of a dynamic seal valve. Quality lapped-spool valves may consume as little as 50 cc/min, but it is more typically 200 to 400 cc/min – compared to leakage of 10 to 50 cc/ min in a bubble-tight packed valve. But the lapped spool valve never changes and has a consistent consumption. In applications that cycle pressurized valves infrequently, poppet valves may be a better choice. |