Troubleshooting Challenge: Two-stage Directional Valve Locks Up

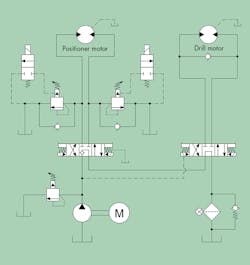

The circuit shown here was used successfully on a conveyor line that processed large concrete paving blocks. Concrete was poured into a rectangular frame about 2 in. deep, the water was pressed out, and the frame was moved onto a carriage to the next station, which drilled a ½-in. hole in one side. The carriage then moved each frame to the next station, where a positioner motor rotated each frame 90 deg., allowing the same drill to bore a hole into a perpendicular side of the block. This was repeated so all four sides had a ½-in. hole, into which reinforcing rods were inserted at the job site to connect all the blocks together.

The drill motor valve was damaged by a crane hook, so a new valve was purchased and installed. The drill would work eight to 12 times, but and then the valve would lock up. Mechanics thought something must’ve been blocking the main spool from shifting, so they disassembled it but could not find anything that could obstruct the pilot or main spool. They reassembled the valve and installed it, only to find it would cycle the drill circuit 10 to 14 times and lock up again.

Any idea what was happening?

Find the Solution

Think you know the answer to this month’s problem? Submit your solution via e-mail. All correct answers submitted by January 8, 2018 will be entered into a random drawing for a $50 gift card. The winner will be notified, and his or her name will be printed in a future issue. Only one gift card will be awarded to any participant within a calendar year.

Solution to Last Month’s Challenge:

When new systems overheat—as the aerospace parts supplier encountered with the new press—the idle time when running the hot case drain directly back to the reservoir must be considered when designing the heat exchanger circuit. The case drain line should be connected to the main return line or through a separate cooler.

About the Author

Robert Sheaf

President

Robert J. Sheaf Jr., is the founder and president of CFC Industrial Training, formerly Certified Fluid Consultants, part of CFC-Solar Inc. CFC-Solar provides technical training, consulting, and field services to any industry using fluid power technology.

Leaders relevant to this article: