Pump-Unloading Circuits

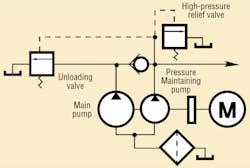

High-low circuit — Many systems require a high volume at low pressure for rapid movement of a vise or tool, then low volume at high pressure for clamping or feeding. This can be accomplished by a high-low circuit using two pumps.

During rapid traverse, both pumps supply the system. When pressure rises during clamping or feed, the large-volume main pump unloads, and the small pump maintains pressure. Output flow of the small pump is low enough to prevent heating of the oil. Instead of pilot operation, the unloading valve can be solenoid controlled and actuated by a pressure switch.

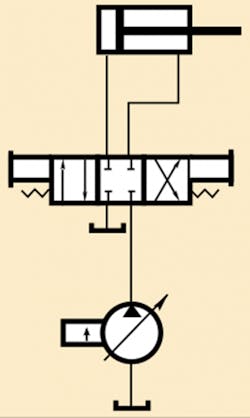

When the open-center system is in neutral, pump output flows through the directional control valve to tank. When this simple circuit handles only low flows and the directional valve spool has tapered lands, it proves to be very efficient. If several cylinders are used, the valve can be connected in series — that is, the tank port of one valve is connected to the pressure port of the next.

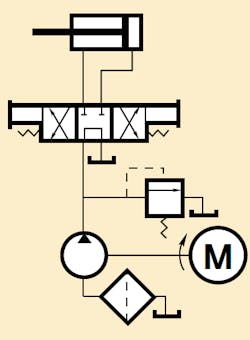

Pressure-compensated pump — A pressure-compensated, variable-volume pump is controlled by system pressure. As pressure increases, displacement of the pump decreases so that pump output at the preset pressure is only sufficient to make up for leakage. Used with a closed-center valve, the pump is stroked to minimum (zero) displacement when the valve is centered.

This file type includes high resolution graphics and schematics when applicable.