Sequencing circuits automatically move actuators in a predetermined sequence. Shown and described here are three useful sequencing circuits using standard components.

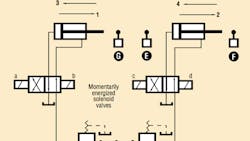

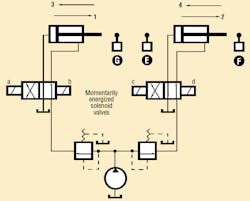

Electrical control — Limit switches momentarily actuated by the cylinders control the solenoid valves to sequence this circuit.

Solenoid a is energized by a pushbutton to initiate movement 1. At the completion of movement 1, limit switch E is actuated to energize solenoid c, initiating movement 2. At the end of movement 2, limit switch F is actuated to energize solenoid b, initiating movement 3. At the end of this movement, limit switch G is actuated to energize solenoid d, initiating movement 4. The sequence valves prevent a pressure drop in either cylinder while the other operates.

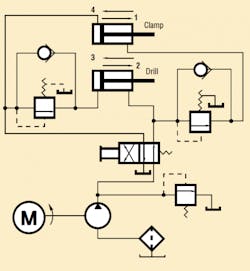

Sequence valves — Several cylinders can be connected to move in sequence on forward and return strokes. In this circuit, a clamp must close before a drill descends. On the return stroke, the drill must pull out of the work before the clamp opens. The sequence valves are arranged to cause pressure buildup when one cylinder completes its stroke, the valve opens to allow flow to the other cylinder.

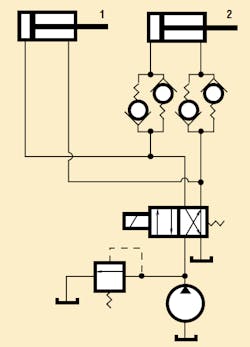

Backpressure check valves — Cylinders may be sequenced by restricting flow to one cylinder. One method of restricting flow is with backpressure check valves. They prevent flow until a set pressure is reached. In this circuit, Cylinder 1 extends and retracts ahead of Cylinder 2.

About the Author

Leaders relevant to this article: