This file type includes high resolution graphics and schematics when applicable.

Many older-generation hydraulic presses and stamping machines employ simple on-off control of two position hydraulic valves to extend and retract the hydraulic actuator that does the work. In such machines, precise control of the ram position may not be a primary requirement, but velocity control can turn into a big issue. Depending on the application, the use of discrete (on-off) hydraulic valves could impact the quality of production units, and may actually be hazardous to a machine’s health.

With on-off control, the actuator stops abruptly when the valve is moved. In a heavy metal-stamping application, the large inertia of the moving parts can lead to damage of the machine and the work piece. A better means of control involves the use of a proportional servo valve and electrohydraulic motion controller, which can control the actuator’s velocity and make the motion smoother to avoid the shock of instantaneous accelerations and decelerations.

This is the rationale that drove Albany, Ore.-based TEKFAB Inc., integrator of high-performance production lines, to use proportional valves and a programmable motion controller in a new line it developed for a manufacturer of steel building studs, Figure 1. Before roll-forming the edges of flat stock to make the legs of the studs, access holes are punched in the material using a compound die that first punches the hole and then forms the edges of the hole for strength—all during a single stroke.

Equipment used previously by the customer made the access holes via hydraulic rams operated by discrete directional-control valves. The gauge of the steel needed to be thick enough so that it wouldn’t tear radially to the desired cut outline when punched by the ram. Also, the speed of the punch was restrained to minimize any possible damage to the machine caused by the shock and vibration of the punching operation.

For the new stud production line, TEKFAB was given the task of speeding up the process, significantly expanding its automation capabilities, and making it more precise and repeatable. On top of that, the company had to deal with lighter-gauge steel than the traditional steel that was formed. “To meet these requirements, we knew that we needed to use an electronic motion controller,” said Rob Taylor, TEKFAB principal.

Selecting a motion controller

TEKFAB called in its local hydraulics distributor and asked for a recommendation. George Wells, Sales Manager of Industrial Power Systems, Portland, Ore., recommended a Delta Computer Systems RMC75 two-axis electrohydraulic motion controller, Figure 2. “I had some experience with Delta controllers before,” said Rob Taylor. “I knew that they could interface easily with proportional valves to both smooth out and speed up the stamping process.”

The Delta RMCs can be programmed to smoothly ramp actuator velocities up and down to avoid step changes in acceleration, the kind of changes that can cause the machine to vibrate and create quality problems in the production units. Instruction sequences for one complete motion profile operation are programmed into the Delta controller, and then the supervisory programmable logic controller (PLC) issues a go command to initiate operation.

Following completion of the operation sequence, the motion controller notifies the PLC that it is done, and the PLC moves the sheet steel into position for the next punching. In the machine, two punches operate in tandem as the metal stock is advanced two hole spaces at a time. With the new controller, the process can be sped up to punch six holes about every second, enabling the machine to produce studs at the rate of about 200 ft/min.

About closed-loop control

The TEKFAB application is typical of those that require closed-loop control. Closed-loop control can bring flexibility, accuracy, precision, and speed to machine operation. “The need for speed isn’t the main issue, though,” said Rob Taylor. “Our customer wanted to be able to produce metal studs with holes arranged in complex geometries, with variable hole spacing, and to do so reliably and repeatedly in thinner sheet stock.”

Closed-loop control compares actuator position information from a feedback device to a desired position, and the motion controller acts to eliminate this difference, which is called the error. The greater the error, the greater the output must be to correct the error. Gain parameters incorporated into the control-loop equation control the speed of the controller’s response. Therefore, a higher gain means a quicker response.

Setting a gain value too high, however, can cause the system to respond too quickly, and the motion may overshoot its intended position. Or a damping term may become too strong, causing the motion to stop short of the target. Setting the gains to be just right is the goal of the control loop tuning process.

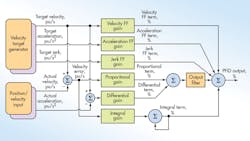

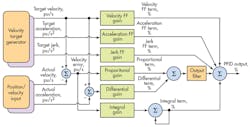

Higher-end controllers augment proportional (P) gain with integral (I) and derivative (D) gain terms, which respond respectively to reduce errors that would build over time, or to errors that would build very quickly. Some controllers employ predictive elements in the control-loop equation called feed forwards. These act to reduce errors that are assumed to occur in the future.

Figure 3 shows the typical control-loop structure for position control (using P, I, and D) and feed forwards for velocity, acceleration, and, if needed, jerk (change in acceleration). The control-loop calculation is updated in real time, so subtle variations in the environment and the reaction of motion components are also dealt with in real time. The more precise the feedback information, the more precise the motion commands sent to the proportional valve, which causes the motion.

The combination of PID, feed forwards, consistent continuous feedback, and a servo or servo-quality proportional valve allows the controller to cause the motion to go to positions via user-programmable velocities, accelerations, and decelerations. The programmable accelerations and decelerations help reduce the wear and tear on the hydraulics and the mechanical systems. In the case of presses, one can ramp down the velocity so that when the tooling hits the work piece, the press will have just the right amount of kinetic energy to do the necessary work—without causing excessive shock or vibration.

Controlling the slot punches

In the TEKFAB metal stud slot punch, the Delta RMC75 two-axis motion controller performs closed-loop position control of each 75-ton punch ram over approximately a 1¾ -in. stroke, using position data from a magnetostrictive linear displacement transducer (MLDT) mounted on each cylinder. Programming the motion controller involves loading the instructions for a motion sequence into registers contained in the controller.

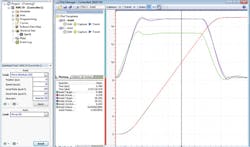

The control loop is tuned with tools provided in Delta’s RMCTools software package. One of the key tools is the Plot Manager, which visually compares actual and target motion profiles and shows the developer when the system is perfectly tuned when the actual and target profiles overlap. Figure 4 illustrates a sample plot.

“Another advantage of using a programmable motion controller is that it provides very flexible control,” said Rob Taylor. “Every order that our customer fills is for customized product, and we needed to enable the machine to produce studs that range from six- to 40 ft-long to meet differing architectural requirements.” The machine also supports stamping heads that, along with the motion program, can quickly be changed.

Operational parameters in the Delta controller can be accessed remotely from the PLC during machine operation or maintenance, or via an attached PC during the application-programming phase. The controller is easy enough to program so that TEKFAB’s customers can make software updates as their needs change. For this purpose, the Delta RMC75 provides a standard Ethernet/IP interface.

This file type includes high resolution graphics and schematics when applicable.

The TEKFAB application is a clear example of the benefits that are obtainable through the use of closed-loop control in metal-forming applications. To ensure delivery of those benefits, the system builder should make sure that he or she chooses a motion controller that supports easy tuning of control loops incorporating P, I, and D terms and feed forwards.

Brad Smith is a Regional Technical Sales Manager at Delta Computer Systems Inc., Battle Ground, Wash. For more information, visit www.deltamotion.com.

About the Author

Leaders relevant to this article: