Mini loaders do away with leakage

First designed in 1980, the Kanga loader was developed as one of the world’s first fully hydraulic “stand-on” mini skid-steer loaders by Jaden Kanga Group, Burleigh Heads, Queensland, Australia. Although early versions topped out at 11 hp and were designed to operate in small, difficult to- access construction areas, today’s equipment covers power ratings to 25 hp.

The low end of the spectrum is now the 13-hp Kanga Kid, introduced in 2000 to provide users with an affordable “motorized wheel barrow.” The Kanga Kid is small enough to be driven through domestic doorways and light enough to be transported in elevators — making it ideal for hauling materials for demolition and construction work in high-rise buildings.

Like their full-size counterparts, these small Kanga models feature all-hydraulic hydrostatic drives. They also accept a full complement of hydraulically driven attachments — buckets, brooms, trenchers, hoes, and most other equipment commonly used on full-size skid steers. Standard models have four wheels, with an optional track drive attachment for difficult ground surface conditions.

Standard hydraulic valves had been producing harsh function control, so considerable research and development was conducted to bring control performance up to today’s international standards. Oscilloscopes were used to study Kanga’s individual hydraulic operations. This led to the development of manually operated control valves modified with spool specific feathering functions to provide smooth operation.

Risk assessments were then carried out to ensure safe operator load balance with self-leveling buckets and fully sealed transmissions being part of safety considerations with product development. Lightweight springs are also fitted to the control valve spools to improve ease of operation.

As production of the standard bucket loader progressed, so did demand on engineering to develop and adapt special- purpose tool attachments. This necessitated modifying the hydraulic system to accommodate these attachments. Manifold cartridge valve assemblies were also developed to maintain constant forward motion tension when using the trencher attachment.

Ongoing development

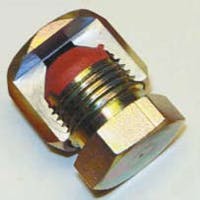

Kanga founders Doug McIlwraith and Alan Porter continue to seek design improvements, one of which being a radio-controlled version for use in hazardous environments or in difficult-to access areas. Their latest development is not as high-tech, but produces impressive results. Kanga upgraded standard JIC flared joints in hydraulic lines with Flaretite seals to hold leakage at bay.

Porter explains, “We were experiencing production line and in-field warranty cost problems from leaking JIC fittings. Since fitting Flaretite seals, we have not had one leaking joint. Flaretite has saved us considerable downtime and rework costs on our production line. As a result, we have reduced customer complaints and warranty costs related to JIC fittings leaking in the field.

“NFPA and ISO recognizes the benefits of compliant seals being fitted to JIC flared type joints. Flaretite seals have not only saved us money and improved our machines reputation, but have helped us address serious environmental workplace issues as well,” concludes Porter.

For more information on Kanga loaders, visit www.kanga-loader.com, or call their US office in Fort Mill, S.C. at (803) 548-4348. For more information on Flaretite, Fenton, Mich., visit www.flaretite.com, or call (810) 750-4140.

Old reliable becomes more reliable