Hydraulic-Electric Analogies: Hydraulic Power Conversion, Part 2

This file type includes high-resolution graphics and schematics when applicable.

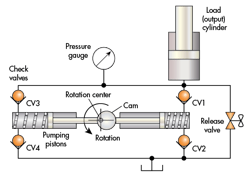

It is now just a simple step to make the pump illustrated in Figure 4 from Part 1 (“Hydraulic-Electric Analogies: Hydraulic Power Conversion, Part 1”) into one that receives mechanical input power via a rotating shaft instead of the reciprocating, manually operated handle. The changes are shown in Figure 5.

The cam has a simple circular shape, but its rotational axis is offset from the circle’s center. It generates the required reciprocating motion to the pumping pistons. The circular cam also imparts sinusoidal motion to the pumping pistons.

An additional change is that the blank end chambers of the pumping pistons have been outfitted with return springs. In the configuration shown, they are essential to ensure that the piston rods remain in contact with the cam at all times and provide return motion to the pistons, assuring that they will fill with reservoir fluid while retracting. The earlier versions of the described pump both engage the link between the input handle and the pumping pistons with a pin and slot, which ensures that the pumping pistons will follow the handle motion.

The most important feature of the pump in Figure 5 is that it can be driven by a rotating machine. Another key point is that more than two pumping pistons can be incorporated, up to the number permitted by the physical size limitations and the strength required of the machine and its structural parts.

In the configuration shown, the multiplicity of pistons would be arranged radially, with the one cam providing the rotary-to-reciprocating motion conversion. Multi-piston pumps usually have an odd number of pistons, because it’s been demonstrated that it will produce the lowest outlet pressure ripple and, thus, the lowest noise. Although the example pumps have pistons arranged radially outward, the majority of commercial pump configurations arrange the multiple pistons axially, making for a smaller-diameter machine.

Check-ball Pumps

Another variation is to use a cam with more than one lobe, so that there will be two pumping cycles per shaft rotation, doubling the output flow in a given package size. In commercial configurations, the inlet check valves are often embedded within the pumping pistons, making a more-compact machine. They are referred to as check-ball or check-valve pumps.

An important limitation of the check-ball pump is that it cannot operate as a motor. To understand this reality, imagine that the rotational shaft is free from any constraints, and then one pushes downward with great force on the output piston rod. That force—no matter how great—cannot be brought to bear on the pumping pistons because of the check valves (CV3 and CV4). Therefore, it precludes any hope of pressure at the output port resulting in shaft rotation. In this case, there’s no direct analogous kind of electrical motor.

The next part of this series will reveal that certain pump designs will function very well as motors, and motors that will run well as pumps. In fact, in many applications, pumps and motors constantly switch from pumping to motoring and vice versa upon the occurrence of accelerations and decelerations. The conventional piston pump that uses a port plate as the ac-dc commutation function is a machine that can both pump and motor.