Dual-mode pressure control

The control system in many press applications is designed to provide position control during rapid traverse toward die closure. As the load is engaged and pressing begins, the pressure builds up, but the pressing quality often is affected by the rate of pressure rise and how long the pressure is held. This requires a special dual mode control algorithm that switches from position control to pressure control in mid cycle. It normally requires some experimentation and calibration in order to function properly. However, the challenge is more tedium than technology.

The moment of transition

The critical point during the motion cycle is the moment of transition from position to pressure control. There are two transducers in the system at all times, both position and pressure. Normally, only one is used at a time. As the cylinder extends under profiled position control, the profile "leads" the cylinder up to the point of load engagement and usually, slightly beyond.

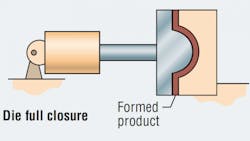

The distance labeled X in the illustration at right represents the slew distance, or no-load travel, at which point the load engagement and increase starts. The specific nature of the engagement depends on the process and may be accompanied by a slowdown or not. In either event, load engagement will result in a pressure rise in the blank end of the cylinder and a drop in pressure on the rod side as the load compresses.

The switching point

At the point of switching from position to pressure control, the position transducer is removed from the loop and is replaced by the pressure transducers. Each one is scaled by its respective piston area, in order to control the press force. This switching is done automatically within the controller.

The transition can be very critical, because the controller must also switch to a new profile that controls the pressure. Basically, the controller must take a snapshot of its current operating conditions — including pressure measurement — and set the new pressure command voltage to be used during the pressure control phase of the machine cycle. If the transition is not done correctly, there is an objectionable jump that takes place because of the change in control loops.

In critical press applications, the jump can result in bad products when not made smoothly. The transition must also be done quickly, lest the information used to make the switch get too old, perhaps as quickly as two or three milliseconds. Some commercial motion controllers have the ability to program position-to-pressure transitions smoothly and accurately.

Each of the two loops has not only its own feedback transducers, but also its own control algorithm and its own gain settings. For example, the position control loop my be done with proportional control only, but the pressure control loop may be done with integral control. Clearly, the control is a task to be done by a digital system, not analog, although the foregoing discussion has implied an analog controller. Some commercial motion controllers are designed specifically to allow for control loop transitions like this in mid-cycle. That is, commercial motion controllers are capable of controlling more than just speed and position. Note further, retraction must be done under position control, so there is another transition, but from pressure back to position to effect retraction. This transition is not normally as critical, as it usually has less effect on the product quality. Uncontrolled transition may result in objectionable noise and jerky operation.

Other considerations

In other systems, there must be pressure control throughout the machine cycle, or at least during the full extension or full retraction portion, but the load changes. Consider there is a cylinder that must extend at some nominal speed, but do so while generating a specific force against some restrictive but non-rigid load. During this portion of the cycle, the load appears to have through-flow because of cylinder motion.

Consider additionally, however, that the actuator eventually encounters a completely rigid load wherein motion ceases, but it is still desired to control or maintain pressure. Certain injection molding machines have load cycles like this. The first part of the cycle has a viscous load reaction increasing many times, as the flowing plastic fills the voids in the mold. The end of the cycle comes when all the voids are filled and the load becomes essentially rigid. At this point, there is high force and nearly zero speed.

In another system, there indeed may be simple through-flow during a portion of the machine cycle, but then the load flow demand changes because of some external factor, such as the independent changing of the degree of opening of the through-flow valve. With through flow, integral control is probably called for, but when the through flow goes to zero, perhaps simple proportional control is better.

These kinds of systems can be challenging — the control algorithm and the loop gains have to be changed to suit each portion of the cycle when the loading changes. Otherwise, instability will occur with the integral turned on or the system is too sluggish and fraught with following error when there is no through-flow. A dual mode digital controller with two different control algorithms and/or gains is the most likely way to deal with this system design challenge.