Hydraulic hybrid promises big savings for UPS

Last year, partners from the federal government and private industry announced they were working together to develop new hydraulic hybrid technology for an urban delivery vehicle — technology that promises dramatic improvements in fuel economy and emission reductions. The goal of this partnership was to establish the best possible business case — highest efficiency and lowest cost — for heavy hybrid vehicles.

Today, that technology is on the road in the form of a UPS delivery truck. In June, engineers unveiled the first-ever series hydraulic hybrid diesel urban delivery vehicle, which was developed through years of research by UPS, the U.S. Environmental Protection Agency, Eaton Corp., International Truck and Engine, and the U.S. Army.

UPS-branded P-100 truck prototypes represent the first-ever hybrid delivery vehicles to use hydraulic technology. The first vehicle will operate a daily delivery route in the Detroit area for a few months. Then, the prototype will be returned to EPA's lab in Ann Arbor, Mich. for analysis. In 2007, similar testing of a second prototype vehicle will occur.

"The hydraulic hybrid technology is quite promising, and we're eager to see how the vehicle performs in a real-world setting," said UPS chief operating officer John Beystehner. "We have led our industry in testing alternative fuel vehicles because fuel conservation is critical to our business. We believe the impact of this initiative will go far beyond our industry."

EPA laboratory tests show that the technology has the potential to dramatically improve the fuel economy of urban vehicles used in applications such as package delivery, shuttle and transit buses, and refuse pickup. By capturing and reusing virtually all the energy created during operations, engineers estimate the EPA-patented technology will achieve 60 to 70% better fuel efficiency in urban driving, with a 40% reduction in carbon dioxide emissions.

A partnership approach

UPS, Eaton Corp., and International Truck and Engine have been working with the EPA and the U.S. Army's National Automotive Center to develop the hydraulic technology for several years. Eaton has actually been working with the EPA since October 2001 under a Cooperative Research and Development Agreement involving hydraulic hybrid systems. As part of the company's role in designing and developing hybrid technologies, Eaton engineers have been co-located at the EPA's Ann Arbor facility.

This partnership approach has benefits beyond advancing alternative fuel technology for commercial fleets.

How it works

Similar to a hybrid electric vehicle, which includes a gas or diesel engine and battery, the hydraulic hybrid vehicle (HHV) includes a diesel engine and a hydraulic power system that, in laboratory testing, has achieved significant fuel economy over traditional UPS vehicles.

Hydraulic hybrid technology includes two power sources that propel the vehicle — a fuel-efficient diesel combustion engine and hydraulic components. This technology replaces a conventional drive train with a hydraulic one, which eliminates the need for a mechanical transmission and driveline.

These vehicles can store energy from the hydraulic system, even after the vehicle is turned off. This storage allows the vehicle to start with this energy, instead of relying on the engine to propel the vehicle.

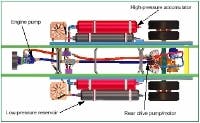

The innovative technology behind the first prototype vehicle is simple. The main components of the system consist of:

- A high-pressure accumulator stores energy, as a battery would in a hybrid electric vehicle, by using hydraulic fluid to compress nitrogen gas stored inside each accumulator.

- A low-pressure reservoir stores hydraulic fluid after it has been used by the pump/motor.

- A rear drive pump/motor converts high-pressure hydraulic fluid into rotating power for the wheels and transmits braking energy back to the high-pressure accumulator.

- An engine pump transmits pressurized hydraulic fluid to the rear drive pump/motor, the high-pressure accumulator, or both.

- A hybrid controller monitors the driver's acceleration and braking actions and commands the hybrid system components.

Three key design features in the full series hydraulic hybrid enable it to provide maximum fuel efficiency:

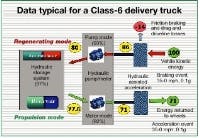

Regenerative braking — When stopping the vehicle, the hybrid controller uses the energy from the wheels by pumping fluid from the low pressure reservoir into the high pressure accumulator. When the vehicle starts accelerating, this stored energy is used to accelerate the vehicle. This process allows hydraulic hybrids to recover and reuse over 70% of the energy normally wasted during breaking. Figure 2 illustrates the efficiencies of hydraulic hybrids.

Optimum engine control — The engine pump pressurizes and transfers fluid from the low pressure reservoir to the rear drive pump/motor, and under certain operating conditions, to the high pressure accumulator. In the full series hybrid design, there is no conventional transmission and drive shaft connecting the engine to the wheels, which frees the engine to be operated at its "best efficiency" speed, to achieve optimum vehicle fuel.

Shutting off the engine when not needed — The unique full series hybrid design not only allows the engine to be operated most efficiently, but also enables the engine to be completely shut off during certain stages of operation — such as when decelerating and when not moving at a stop. As a result, in certain stop-and-go urban city driving, engine use is cut almost in half.

Building a hydraulic hybrid

It is expected that high component durability should yield regular vehicle maintenance and troubleshooting procedures that are simple and more like those found in conventional mechanic vehicles, and thus more efficient and economical.

The EPA built two different hydraulic hybrid prototypes to explore two different sets of benefits from using hydraulic power. Prototype #1 was designed to demonstrate a heavy hybrid with very high fuel economy improvement with lowest possible cost when manufactured in high volumes to yield the best possible business case. Prototype #2 was designed to explore other engine and hydraulic hybrid drivetrain configurations.

Prototype #1 — The hardware configuration of the first prototype full series hydraulic hybrid UPS package car is shown in Figure 3. This vehicle includes an integrated hydraulic hybrid rear drive assembly, consisting of three hydraulic pump/motors integrated into the rear axle. The front two pump/motors of this assembly are capable of performing regenerative braking. The single rear unit is an auxiliary hydraulic motor for additional torque up to 17 mph. There is also one engine hydraulic pump, which generates fluid flow when needed. The energy storage system consists of four hydraulic accumulator vessels, two for high pressure fluid (up to 5000 psi) and two for low pressure fluid (up to 180 psi). The entire closed-loop fluid system holds about 22 gal of transmission fluid. Production systems could be designed with smaller storage systems.

Initial laboratory test results for this vehicle showed greater than 70% improvement in fuel efficiency with a corresponding 40% reduction in CO2 emissions. The EPA estimates that with $2.75/gal fuel cost and projected high volume manufacturing costs of $7000, this hybrid would have a return on investment of less than three years and deliver a lifetime (20 yr) fuel and brake maintenance savings of more than $50,000. This vehicle will begin on-road testing by UPS during 2006. Additional durability and laboratory testing will continue into 2007.

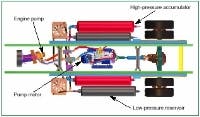

Prototype #2 — The hardware configuration of the second prototype UPS package car is shown in Figure 4. This vehicle has a different full series hydraulic hybrid drive assembly, consisting of a single pump/motor coupled with four-speed computer shifted clutch-less transmission. It has a similar engine pump and energy storage accumulator system.

Modeling results for this vehicle predict about a 50% improvement in fuel efficiency. Full system integration is still underway for this vehicle and initial laboratory test results have not yet been performed. Work on this vehicle will continue into 2007, with Phase 2 efforts that include installing a different diesel engine utilizing EPA's Clean Diesel Combustion technology to demonstrate clean diesel operation at 2010 levels without any NOx aftertreatment.

Fuel efficiency

Recent advances in hydraulic pump/motors and accumulators have enabled cost-effective full series hybrids. Advances in these hydraulic components have shown that the efficiency of the overall series hydraulic drivetrain is capable of competing with the on-road efficiency of conventional mechanical drivetrain systems in urban settings.

The advanced bent-axis hydraulic pump/motors used in these delivery vehicles have been shown to have peak efficiencies of 95% with the overall cycle conversion efficiencies averaging near 90% over the EPA city driving cycle.

If, during braking, the anti-lock brake system (ABS) on the truck detects an "ABS brake event" such as skidding or sliding on ice, then the pump-motor's displacement control is capable of quickly terminating the hydraulic braking, so that the ABS system can control braking exclusively using the truck's foundation brakes.

Advances in hydraulic accumulator vessels have also contributed to the efficiency of these vehicles. The accumulators used in these delivery vehicles are carbon fiber vessels rated for 5000 psi operation. They are about 90% lighter than comparable steel vessels and yield >98% input/output efficiency. Safety valves and controls have been integrated into the accumulators used for these vehicles.

A rolling test lab

For decades, UPS has used its fleet as a "real-world" test lab for alternative fuel technology. This rolling laboratory strategy means that alternative fuel vehicles are used as a way to study how the technologies would work on a larger scale. Instead of committing to any one technology, UPS is focused on making sure the new technologies work within its fleet, that it meets and exceeds expectations, and that it is viable for implementation on a larger scale.

Following this strategy for hybrids, UPS will test the first HHV during 2006 on a city route in the Detroit area. The hydraulic hybrid package delivery vehicle will be given a UPS route no different from traditional package cars. It will pick up and drop off packages just like the rest of the delivery fleet. The only differences expected will be significantly better fuel efficiency, which means fewer stops at the fuel pump, and reduced vehicle emissions.

While UPS has tested other alternative fuel technologies as part of the rolling laboratory — from natural gas and propane to electricity and hydrogen fuel cells — this marks the first hydraulic technology to be measured. UPS will use the results of these in-service tests to guide future decisions regarding hydraulic hybrids.

These hydraulic hybrid vehicles represent the highest fuel efficiency and lowest cost (potential) hybrid powertrain known to date, Figure 5. They have shown that this technology integrates well into urban delivery vehicles and promises to provide sustainable transportation combined with environmental and energy savings. Nationwide, if half of all urban delivery vehicles used this type of hydraulic hybrid technology, we could amass $1.5 to $2 billion in fuel cost savings and reduce emissions of CO2 by 8 million metric tons annually.

In short, the numbers just add up, not just for UPS, but for the nation as a whole!

Robert Hall is fleet environmental manager for United Parcel Service, and John J. Kargul is director of technology transfer, Office of Transportation and Air Quality, for the U. S. Environmental Protection Agency.

About the Author

Leaders relevant to this article: