Gear motor has dual output

Appeared in print as "Clutch pair and fluid motor make neat package"

Steven Peek, P.E., an engineer at a manufacturer of road construction equipment, was looking for way to speed up roadway resurfacing of a machine. He decided on implementing the Ralumac process, where aggregate, Portland cement, water, emulsion, and additives are stored separately on the resurfacing vehicle. Materials are mixed automatically at the job site and then conveyed to a screed box at the road surface while the vehicle creeps forward at 90 to 180 ft/min or less. This method lets traffic resume on the new surface in only about 15 min.

But ingenuity was required to build the equipment to put the concept into practice. The package of controls, hoppers, conveyers, and hardware had to be mounted on a 3-axle, 10-wheel heavy truck. Because exacting material proportions were essential, it was important for the operator to have the ability to cut off either the aggregate or emulsion feed when required. Space was at a premium, so drive size was an important consideration. Peek solved part of the problem by creating a “two-headed” hydraulic motor.

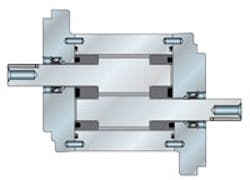

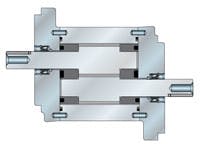

Starting with an off-the-shelf gear-type hydraulic motor with a standard single output shaft, he removed the motor's blind end plate and the idler gear behind it. Then he installed a second shaft-end-plate-gear assembly, identical to the one on the other end. Finally, he mounted a hydraulic clutch on each shaft of the now dual-shaft motor.

With the clutches engaged, the motor feeds aggregate and emulsion to mix at the specified rate; but when necessary, the operator can stop either one or both. The clutch-motor-clutch package does the job functionally and fits right into the tight space.

This type of modification to components should only be attempted by qualified personnel because of potential danger. However, the modified motor was deemed acceptable in this case because the resurfacing machine did not require full torque from either motor shaft. Had the motor been required to deliver full torque from both shafts simultaneously, fluid pressure would've had to exceed the pressure rating of the standard motor.

Steven Peek, PE, is owner of Speekpe, a Sacramento consulting firm with expertise in SolidWorks and mobile hydraulics. For more information visit www.speekpe.com.