Electrohydraulics saves energy in excavator

Doosan Infracore, Seoul, South Korea, began manufacturing excavators in 1977 and has incorporated additional benefits with each new model introduced since then. Doosan’s DX180LC is no exception. Like its predecessors, the DX180LC relies heavily on hydraulics for propulsion, turret swing, and multiple-axis boom. However, the excavator ties in sophisticated elecrohydraulic control with equally sophisticated electronic engine control. This allows the machine to match engine power with hydraulic demands, ultimately resulting in high productivity and fuel economy. Upgrades to ergonomics and machine reliability, coupled with less-demanding regularly scheduled maintenance all add up to higher productivity and efficiency for the DX180LC.

Electronics meets hydraulics

The DX180LC is powered by a Doosan DL06 common rail engine, which produces 118 hp while running at only 1950 rpm. Its high-torque output provides more-efficient operation of the machine’s hydraulic system than with engines running at higher speeds. Furthermore, a CAN communication link ties the engine’s electronic control unit in with the machine’s Electronic Power Optimizing System (EPOS), which controls the hydraulic system. The result is a continuous exchange of information between the engine and the hydraulic system that optimizes efficiency of the hydraulics for all working conditions and minimizes fuel consumption of the engine.

The EPOS makes operation easy and user friendly. Electronic joystick control provides precise movement to make difficult maneuvers simpler. It also ensures maximum efficiency under all conditions, and its automatic deceleration mode provides additional fuel savings.

The EPOS also has self-diagnostic functionality so that any malfunctions can be resolved quickly and efficiently. An operational memory provides a graphic display of the status of major hydraulic functions and other operations of the machine.

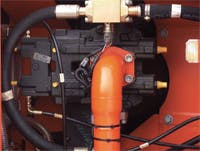

The hydraulic system itself is powered by a pair of 40-gpm variable-displacement axial-piston pumps. A 4.9 gpm gear pump provides pilot pressure for controlling each piston pump’s swashplate angle, to actuate solenoidcontrolled, pilot-operated valves, and other functions. A cross-sensing pump system monitors hydraulic power for each pump so that each draws only the power it needs from the engine, thereby saving fuel.

The hydraulic system enables independent or combined operations, with two travel speeds and two working modes. Working pressure for the excavator’s boom, arm, bucket, and hydrostatic drive is 324 bar. However, high-power mode for the working circuits can reach 350 bar.

A motor for the excavator’s swing drive operates at slightly lower pressure: 264 bar. This lower pressure, combined with pressure damping components in the circuit, helps reduce torsional shock when the excavator turret is pivoting. However, the motor is sized large enough to provide plenty of torque for the brisk acceleration needed for high productivity.