It's not hard to find agricultural equipment with shared filtration for hydraulic and gear oil — a shortcut that reduces cost but may sacrifice filtration effectiveness. Here's an alternative.

Lubricant consolidation reduces cost and simplifies maintenance by using one or only a few different types of hydraulic fluid and lubricating oil in a given machine. But consolidation must be implemented carefully to avoid having overall costs exceed those of a system using multiple fluids. This can occur if the single fluid costs more than the combined costs of two or more individual fluids or if fluid characteristics have been sacrificed to where reliability suffers.

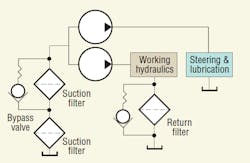

Some agricultural equipment takes lubricant consolidation one step further by consolidating not only fluids, but fluid filters as well. For example, a machine may use the same fluid and filters for hydraulic oil that also lubricates gear drives. In these applications, a fine-mesh suction filter protects hydraulic components from contaminants generated by the gear drive — due mainly to wear on gears, wet brakes, and clutches.

A filter in the return line of the hydraulics ensures the level of oil cleanliness that the system requires. Typically, the fine-mesh filter and return filter are spin-on configurations. In some cases, a separate suction strainer is also installed in the gear housing to protect the hydraulic components from coarse particles when the suction filter bypass valve opens.

There are two drawbacks to this concept: one is the poor cold-start behavior, due to the use of suction filters connected one after another together with relatively long suction pipes. The other is the need for at least two filters. This not only leads to high costs when the system is equipped for the first time, but also increases the numbers of maintenance points and spare parts.

A departure from convention

A new filter concept has been developed as part of a new tractor design. This system, which was implemented within a short period with participation from a hydraulic components system supplier, overcomes limitations of conventional solutions. The development objectives: better filtration and a significant reduction in system and maintenance costs.

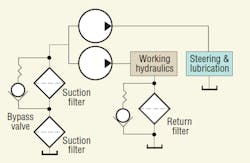

The initial basis was the return-suction filter concept for systems with a closed-loop hydrostatic drive and open circuit working hydraulics.

In this application, oil from the system return flow (closed and open circuits) flows first through an ultra-fine filter element before reaching the hydrostatic pump. The excess between the return and suction oil flows back into the tank after filtering. For the whole system to function, the return flow must exceed the flow of the hydrostatic pump under all operating conditions.

The open-circuit pump draws oil directly from the tank, without protection in most cases. Because the dirt present in both circuits is always filtered in the return flow, it is harmless if no relevant built-in contamination exists in the tank.

However, in systems with shared oil management for the hydraulics and the gearbox, protecting the pumps and downstream components is critical because a large portion of solid contaminants is generated by the gearbox. This leads to an obvious conclusion: as in the classical return-suction filter, the ultra-fine-filtered oil from the return flow of the working hydraulics should be made directly available to both pumps. On average, then, only the quantity for the steering pump needs to be drawn from the tank through a suction filter.

System benefits

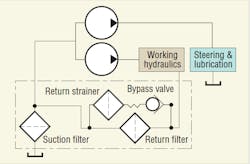

Oil in the return line flows through the return filter element and is directed to the suction port o f t h e pumps for steering, lubrication, and the hydraulic system. When cylinders extend and retract, the oil quantity varies depending on the differential piston area ratio. If the quantity of oil in the return flow is less than the quantity supplied by the working pump (due to difference in volume between the two ends of the cylinder), both pumps draw oil directly from the tank through a suction filter and the second suction port. If any surplus exists when the cylinders retract, fluid flows back to the tank through the suction filter element. An integrated bypass valve protects the return filter element against overload during cold starts. The downstream valve protection strainer prevents coarse particles from entering the system when the bypass is open.

Benefits of the new return-suction filter include:

- excellent cold-start properties compared to conventional systems. The fluid drawn directly from the reservoir is considerably less than that with conventional systems, leading to much better cold-start properties and much lower risk of cavitation damage.

- downstream components are protected. The valve protection strainer in the bypass line protects downstream components from coarse particles during a cold start.

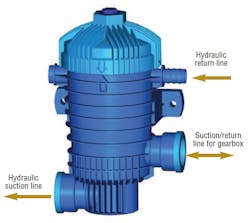

- all functions are integrated into one filter housing made of high-strength plastic, so only one filter is needed for the entire hydraulic system. The innovative connection concept makes it easy and inexpensive to fit the return and suction lines with plug-in connectors and O-ring seals.

- maintenance costs are cut. Just one combined filter element (re-turn filter element with bypass valve, protective strainer, and suction filter element) is used for the entire hydraulic system. This simplifies maintenance by making the filter easily accessible, and the filter element can be changed in seconds. Plus, intervals between services can be twice as long as with a conventional system.

Summary

This discussion illustrates how products can be created on the basis of existing technical solutions, with appropriate application know-how and intelligent concepts. Technical improvements are even more welcome when user benefits are significantly increased thanks to reduced system and maintenance costs.

Larry Gerken is general manager at Argo-Hytos, Bowling Green, Ohio. For more information call (877) 377-2746 or visit www.argo-hytos.com.