Fluid analysis keeps the life in mobile equipment

Maintaining clean hydraulic fluid is crucial to keeping mobile equipment in good health — and keeping it up and running longer at peak operating performance.

A good way to ensure clean hydraulic fluid is to perform routine fluid analysis checks, which detect the fluid contaminants that cause up to 80% of hydraulic system failures. Some hydraulic component manufacturers are equipped with ISO-certified labs that provide fluid testing and diagnostic services for their customers.

A hydraulic blood test Fluid testing labs are high-tech operations. These labs analyze hydraulic fluid samples in much the same way as medical labs test blood samples. Just as a blood test helps a doctor diagnose health problems, a sample of hydraulic fluid can help pinpoint sources of contamination and determine whether or not a system has adequate filtration.Analysis services help reduce catastrophic equipment failures, maintain optimum component performance, and identify any substandard maintenance practices. The result is often increased productivity for the user.

The testing process

The analysis process begins by drawing hydraulic oil or lubrication fluid from a system when it is at normal operating temperature. Lab-equipped manufacturers of hydraulic products generally provide analysis kits with ultra-clean specimen containers, which are to be filled with the fluid flowing out of a system's sampling valve, sump drain, or reservoir drain. All surfaces need to be extremely clean during sampling to avoid contamination, which can affect the accuracy of fluid testing.

Some labs provide two kit styles (for testing with and without spectrographic analysis), allowing for different levels of testing. A user simply places a filled specimen container in the kit's shipping container and mails it to the lab. Users can opt for any method of shipment, since the age of the specimen generally does not affect testing results.

Once at a lab, sophisticated computer programs and laboratory diagnostic equipment are used to test hydraulic or lubrication system fluid samples that are drawn from the user's equipment. Testing may include:

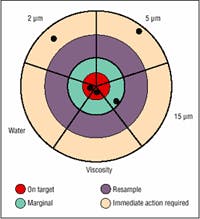

photomicrography — detects fluid contaminants, including size and type.Once testing is complete, users are provided with the findings, which may include photos of the contaminants and tips on how to improve or maintain current fluid conditions. Conducting trend analysis, by comparing data from two previous samples, with current results, may also be meaningful.

Interpreting findings

Some common problems found in fluid samples are:

- elevated water content — due to ingression into the reservoir during equipment servicing or fluid refilling

- elevated particle count — due to inefficient filtration of particles, such as oxidized metal from fill fluid or system piping, steel from valve or pump wear, silica or fiber from external ingression or process operation, and

- oxidation — due to high system temperatures causing a reaction between the oil and oxygen, which can form sludge in the oil, lacquers, and varnishes on hot surfaces.

Some labs will provide an analysis report within 24 hours of fluid sample receipt. The report includes tips on improving or maintaining current fluid conditions and compares data from two previous samples, if available, with results of current samples. Viewing results of three side-by-side samples aids in easy recognition of trends that may indicate increased levels of contamination.

Labs also may offer guidance on what to do about contamination. Based on the type of metal content found in a fluid, they could recommend that users check on specific system components that may be wearing out and releasing particles into the fluid.

Selecting a lab

Because many fluid analysis labs are available, be sure to

look for one with experience, a full range of testing capabilities, ISO certification, and quick turnaround time. The most reliable labs will provide the best fluid evaluation — and the best means to improve and maintain the health of your hydraulic fluid.

Wassan Shaffou is lab manager for Eaton Corp., Southfield Mich. Visit hydraulics.eaton.com/services/ fluid_analysis for more details on Eaton's lab.

lubrication fluids. The TWS-C measures water content relative to the percent saturation of the fluid, and ranges from zero (indicating the absence of water) to 100 (indicating 100% water). It is suitable for a variety of applications, including laboratory equipment.

A special capacitance sensor absorbs water molecules from the fluid and changes the capacity value that is directly related to the saturation level of the fluid. An integrated thermoelement on the sensor measures the temperature of the fluid in the range of 13° to 212° F ( 25° to 100°C). Both this value and the degree of saturation are reported as a 4 to 20 mA signal.

The TWS-C can be directly installed into the hydraulic system with a threaded connection. It is recommended that the sensor be mounted vertically in a known turbulent area with the mechanical connection pointing upwards in hydraulic applications. Additionally, the sensor should be fully submerged with fluid free-flowing around the sensor.

For more information, visit www.schroederindustries.com

About the Author

Leaders relevant to this article: