Cleanliness Programs are Key to Keeping Oil and Hydraulic Fluids at Their Best

Companies that rely on lubrication and hydraulic fluids have a vested interest in keeping those fluids clean and operating at their best for as long as possible. But some companies might not be aware of what the current standards on cleanliness are and how to begin what could be a cleanliness program that spans several facilities and hundreds of machines.

Here’s a quick look at the current standards and the best way to achieve them in even the largest companies.

Setting the Standards for Cleanliness

The International Organization for Standardization (ISO) provides the most trusted and up-to-date guidance for manufacturers, operators and service technicians on the best contamination control for machinery of all types. It has global teams that study cleanliness levels in OEM equipment and recommend expert guidelines for ensuring the best fluid cleanliness based on four international contamination control standards: ISO 11171, ISO 11943, ISO 16889 and ISO 4406.

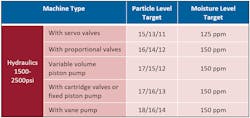

For example, the ISO Solid Contamination Code (ISO 4406:2021, the Method of Coding the Level of Contamination by Solid Particles) is recognized as the gold standard for specifying the best contamination control in equipment. It breaks down precisely how many particulates are in an engine based on what is found in a 1 ML sample of a fluid. It also identifies those contaminants based on three size ranges: > 4, > 6 and > 14 microns.

Benefits of Clean Fluids

Meeting ISO fluid cleanliness codes for hydraulic and lubrication fluids generates a host of cost-savings and benefits. These include:

Decreased downtime. Contaminated fluids are a leading cause of equipment breakdowns and lost productivity. Investing in a rigorous cleanliness program can prevent tremendous costs just in lost downtime. For example, lost production in a paper mill can cost as much as $12,000/hr. Factor in equipment repair or replacement over time, and it’s easy to see why effective contamination control programs save money.

Extended fluid life. Disposing of and replacing contaminated fluid can be a major expense. Maintaining adequate cleanliness standards rather than frequent wholesale oil replacement is a major cost benefit.

Reduced waste and supplies. Implementing fluid cleanliness standards extends filtration service life and reduces the frequency of change-outs. Every filter change is estimated to result in a 5 to 10% fluid loss, along with the additional costs of replacing that fluid and the labor involved.

Lower labor costs. Although it may seem counterintuitive, maintaining higher cleanliness standards reduces costs associated with complete oil changes, component changes and other labor-intensive activities. These activities can create larger or less predictable blocks of downtime that whittle away at the bottom line.

Reduced energy costs. Contaminated fluids have higher viscosities, which make pumps work harder and the filter to load quicker, so pressure increases faster. With clean fluid in the system, pressure across the filter takes longer to build so the pumps don’t work as hard, thus saving energy.

OSC: A Step-by-Step Approach

As a company plans it ISO-approved cleanliness program, there are critical initial steps to take:

1. Evaluate and establish cleanliness levels using global ISO codes. Identify and document target cleanliness levels for each fluid and corresponding piece of equipment using ISO Code ISO4406:2021. Global OEMs can provide specific codes that will best improve performance for specific equipment.

The ISO standard quantifies contamination levels per milliliter of fluid for three sizes of particulates: 4, 6, and 14 µ[c]. They include three scale numbers that represent the range of particle counts per milliliter for each particle size. These counts are combined into a single code number. Each time a code increases, the quantity of particles doubles. What may seem a minor shortfall in hitting a code represents a significant decrease in that fluid’s cleanliness.

To get the most from establishing a cleanliness program with ISO codes, all parties responsible for fluid cleanliness (i.e., any service provider) must closely follow the standards.

2. Choose the right filter media for the job. A cornerstone of the ISO Solid Contamination Code is to assign the proper cleanliness levels based on specific filtration media used in a system. That makes it critical to match the ISO 4406 Cleanliness Code to the filter rating specified for your specific equipment for the most protection and reliability.

Filtration ratings from supplier provide a guide for specifying filter media to support target ISO codes. Filtration evaluation criteria should include fluid compatibility, pressure-flow drop, dirt capacity and other technical requirements.

Using the filter media that can filter to a target code provide cost savings (ROI) quickly on a per-job basis or over time. And media with longer service live adds to those savings.

It’s important to independently or in partnership with a filtration supplier to conduct bi-annual reviews of available filtration technology using clearly defined evaluation standards. Findings may reveal new opportunities to improve the ROI of filtration media and further increase profitability.

3. Establish an oil analysis program and sampling schedule. Regular oil analysis provides three valuable indicators for fluid cleanliness programs:

- Current state of fluid cleanliness.

- Efficacy of the contamination controls.

- Presence of upsets or abnormal conditions.

This data helps determine the appropriate proactive (or reactive) steps to support fluid and system performance. Some steps might seem expensive, such as using spectroanalysis, but they are minor compared to the cost of fluid replacement or equipment repair.

Fluids should be checked monthly and tracked overtime to uncover trends and problems. If budget or personnel restriction prevent this, quarterly analysis and tracking will still provide program benefits. Changes in element compounds, such as iron or brass in the fluid, may identify equipment wear entering and contaminating the system. Filtration suppliers can help in establishing a regular fluid analysis program and scheduling fluid sampling.

4. Filter all new fluids. New fluids are not clean. It has become common practice to bypass this initial filtering to cut costs. But the price of high-quality, cost-efficient filtration of new fluids is substantially less than the cost of letting contaminated oil into a system.

When it’s necessary to add or replace fluid, the new fluid should be filtered to meet the minimal threshold of the company’s established ISO standards, if not to one scale number above those target codes.

If you outsource this responsibility, talk to the service provider about the costs of cleaning new oil to meet the ISO standards. Then conduct a joint review of their filtration equipment to assess its cost effectiveness following the guidelines in step 2.

5. Seal all reservoirs and bulk tanks. The air is filled with contaminants smaller than 40 microns and invisible to humans. If reservoirs and tanks aren’t completely sealed, these contaminants can easily get into the fluid and hydraulic system and wreak havoc. If the reservoir breather is never checked or replaced, it directly degrades fluid cleanliness, which in turn lowers fluid performance and raises operating costs.

6. Check lines for leaks and minimize them. Leaks fluid-carrying lines put a double-dip into your bottom line made up of the costs to replace the fluid and the cost of ridding the system of any contaminant that got in through the leak or the repair process.

The small cost of replacing an O-ring is less than that of replacing oil or damaged equipment. A thorough monthly review of the system to check for leaks enhances the value of a cleanliness program. When it is synchronized with monthly oil analysis, it can efficiently track completion of both tasks.

If maintenance managers find it too challenging to adopt ISO cleanliness codes for every system component at the same time, they can opt for a step-by-step approach to standard adoption. For example, they can begin with one area. Then, as good maintenance habits are developed, challenges corrected and results tracked, the program can be expanded to cover other areas. Profits will increase as each new area is brought under the standards.

Partner with World-Class Suppliers

When maintenance leaders can work with their filtration supplier to implement cleanliness initiatives, both partners can profit.

Fluid power and industrial hydraulic filtration suppliers can be trusted resources and committed partners in reducing costs by “managing” contamination. They can provide training, evaluation, scheduling, analysis, and reporting working in a disciplined approach to oil decontamination. The team approach between company staff and filtration suppliers will help control costs.

The entire team can include facility managers and maintenance professionals, along with service providers such as oil reclamation companies—and with suppliers such as filtration firms—to revise and follow maintenance standards that create facility-wide savings.

Remember, the financial rewards from being proactive in reaching total level cleanliness far outweighs the small investment made in more rigorous maintenance practices.

Ivan N. Sheffield is director of filtration at Des-Case, a manufacturer of filtration products.

About the Author

Ivan N. Sheffield

Director of Filtration, Des-Case

Leaders relevant to this article: