- Secure the cylinder with its service ports up.

- Fill both sides of the cylinder with clean hydraulic fluid through its service ports.

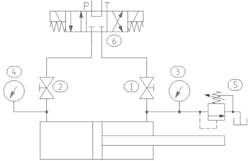

- Connect ball valves (1) and (2), gauges (3) and (4), relief valve (5) and directional control valve (6) as shown in Figure 1.

- With ball valves (1) and (2) open, stroke the cylinder using the directional control valve (6) multiple times to remove all remaining air from both sides of the cylinder - take care not to 'diesel' the cylinder.

- Position the piston rod mid-stroke and close ball valve (2).

- With the adjustment on the relief valve (5) backed out, direct flow to the rod side of the cylinder.

- Increase the setting of relief valve (5) until the cylinder's rated pressure is seen on gauge (3).

- Close ball valve (1) and center directional control valve (6). Note: it is assumed that the hydraulic power unit used to conduct the test has its own over-pressure protection - not shown in Figure 1.

- Record the respective pressure readings on gauges (3) and (4) and monitor any change over time.

If the ratio of effective area between the piston and rod side of the cylinder is 2:1, then if the rod side of the cylinder has been pressurized to 3,000 PSI, gauge (2) on the piston side should read 1,500 PSI. If the differential pressure across the piston is not maintained, this indicates a problem with the piston seal or tube.

Under no circumstances should flow be directed to the piston side of the cylinder with ball valve (1) closed. Failure of the cylinder and/or personal injury could result. When conducting this or any other hydrostatic (pressure) test, always wear appropriate personal-protection equipment.

REMEMBER: pressure intensification in a double-acting hydraulic cylinder is a potentially dangerous phenomenon. And failing to consider its implications can be a costly mistake. To discover six other costly mistakes you want to be sure to avoid with your hydraulic equipment, get "Six Costly Mistakes Most Hydraulics Users Make... And How You Can Avoid Them!" available for FREE download here.

About the Author

Brendan Casey Blog

Author

Brendan Casey is a war-weary and battle-scarred veteran of the hydraulics industry. He's the author of The Hydraulic Troubleshooting Handbook, Insider Secrets to Hydraulics, Preventing Hydraulic Failures, The Definitive Guide to Hydraulic Troubleshooting, The Hydraulic Breakdown Prevention Blueprint and co-author of Hydraulics Made Easy and Advanced Hydraulic Control. And when he's not writing about hydraulics or teaching it, Brendan is flat-out helping consulting clients from a diverse range of industries solve their hydraulic problems. To contact him visit his company's Website:

www.HydraulicSupermarket.com

Leaders relevant to this article: