Think First, Then Troubleshoot — Chapter 11: Pressure-reducing Valves

Chapter 11: Pressure-reducing valves

Pressure-reducing valves (PRVs) maintain secondary, lower pressures in branches of hydraulic systems. (Upstream main system pressure is still determined by the system relief valve or other pressure-setting device.) Pressure-reducing valves are normally open, 2-way valves that allow system pressure fluid to flow through them until a set pressure is reached downstream. They then shift to throttle flow into the branch.

Pressure-reducing valves are actuated by forces exerted by pressure downstream. These forces establish the desired working pressure by creating a pressure drop across the valve’s spring-biased main spool. A pressure-reducing valve is not an on-off device: the position of its main spool adjusts continuously to maintain the desired pressure setting. Of all pressure-control valves, pressure-reducing valves are the most sensitive to contamination-related malfunctions.

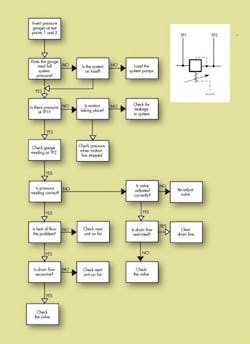

A pressure-reducing valve can malfunction in a variety of ways. To troubleshoot a pressure-reducing valve, refer to Figure 14 and install pressure gauges to read inlet pressure at test port TP1 and outlet pressure at test port TP2. Use these readings to examine:

Decaying set pressure (low pressure at port TP2). If pressure at the outlet port drops below the desired set pressure, check the pilot head spool and seat for excessive wear which may permit increased drain flow. Excessive drain flow through this section of the valve reduced the pressure needed in the chamber above the amin spool to increase valve pressure drop and limit operating pressure in the branch circuit.

Valve will not hold reduced-pressure setting (high pressure reading at port TP2). If preset pressure exceeds desired values, check for a:

- Plugged pilot drain line which would increase pressure in the chamber above the main spool, allowing main system pressure fluid to flow into the branch circuit.

- Or the main spool is stuck in the open position because contaminants are wedged between the spool and its bore

- Or the main spool or bore is scored, or both are scored.

Valve cannot be adjusted to desired low-pressure setting (high pressure reading of port TP2). If the valve cannot be adjusted to its desired pressure setting after the adjustment knob has been turned to its closed or nearly closed position, check for:

- Spool or bore wear which would allow main system pressure fluid to flow to the branch circuit, or

- A broken spring in pilot head, resulting in inadequate spool-to-seat force in the control head.

Fluctuating pressure or no pressure at output port (zero pressure reading at port TP2). If there appears to be no fluid pressure at port TP2, check to establish if:

- The main spool is stuck closed, allowing no pressure fluid to flow to the branch. This condition can be caused by contaminants plugging the orifice in the passage connecting the two ends of the main spool, upsetting the hydraulic balance between the pilot pressures in the lower and upper control chambers.

- The main spool is stuck closed because of contaminants or scoring of the spool, its bore, or both.

About the Author

Alan Hitchcox Blog

Editor in Chief

Alan joined Hydraulics & Pneumatics in 1987 with experience as a technical magazine editor and in industrial sales. He graduated with a BS in engineering technology from Franklin University and has also worked as a mechanic and service coordinator. He has taken technical courses in fluid power and electronic and digital control at the Milwaukee School of Engineering and the University of Wisconsin and has served on numerous industry committees.

Leaders relevant to this article: