Richard J. Mitchell held many technical positions at Vickers Inc., Troy Mich., which is now part of Eaton Hydraulics, Eden Prairie, Minn. He wrote a series of 12 articles describing a systematic approach to diagnosing malfunctions in hydraulic systems. Hydraulics & Pneumatics published this series in every other issue beginning in February 1989 and ending in December 1990.

The information contained in this series is just as valuable today as it was nearly 25 years ago, so it would be a shame to just leave all this valuable information only as printed pages in our archive library. Therefore, I have retrieved all 12 chapters from the series and will be reproducing each in successive editions of The Hitch Post. Following is Chapter 1, from the February 1989 issue:

Think first, then troubleshoot!

Chapter 1: Technical knowledge with mental discipline is the key to logical, efficient troubleshooting

Improper troubleshooting procedures often result in unnecessary and costly hydraulic repairs — wasting time, money, and productivity. All too frequently the individual responsible for troubleshooting a machine hastily and arbitrarily decides that the problem is a faulty pump. Not unexpectedly, after the pump is replaced, the system still will not work.

An organized troubleshooting approach can eliminate such wheel spinning, but for such a program to be effective, it is essential that personnel be fully aware that:

- Leadership and direction originate with top management.

- Lower maintenance costs and higher productivity through reduced downtime are the main objectives.

Mental discipline

Effective and productive troubleshooting is not a complicated process. Clearly, the first prerequisite is technical knowledge, but equally important is mental attitude. In addition to understanding machine operation, as well as hydraulic components and circuitry, the individual must also have the training and discipline necessary to troubleshoot a hydraulic system in a logical and orderly manner.

Quick and efficient hydraulic troubleshooting requires that workers follow logical steps to locate malfunctions in the shortest possible time. The challenge in resolving this problem consists of two steps:

- Think through and identify the elements that might contribute to a system malfunction.

- Avoid jumping to incorrect and illogical conclusions which may result in improper and inappropriate actions.

Background

Within any company, troubleshooting personnel have different levels of competence, manual skills, and experience. For this reason, it is absolutely necessary that before individuals are assigned the task of troubleshooting hydraulic systems, they become intimately familiar with:

- hydraulic terminology

- standard graphic symbols

- component function and operation

- circuit diagram interpretation

- machine and system operation, and

- malfunction troubleshooting procedures.

If troubleshooters are not fully conversant with these elements, any program is likely to fail.

Sample machine

To relate the troubleshooting procedures described in these articles to an actual machine, consider a surface grinder in which the machine’s reciprocating motion passes a work piece back and forth under a grinding wheel. Proper operating requirements include:

- accurate table inching for setup

- variable table speed

- smooth table reversal and intermediate stopping

- control of grinding speed when travel direction is reversed, and

- grinding motion in forward direction that is controllable to adjustable fixed positions.

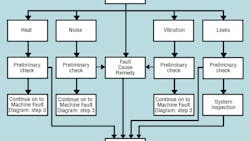

Knowing the surface grinder’s performance specifications is a prerequisite to successful troubleshooting. The machine malfunction procedure, which will be discussed in the next installment, provides a logical sequence of thought and action, which can be applied to the surface grinder or to any other hydraulic machine that develops a malfunction.

Coming next: Identify the machine malfunction and the components that might be the cause.

About the Author

Alan Hitchcox Blog

Editor in Chief

Alan joined Hydraulics & Pneumatics in 1987 with experience as a technical magazine editor and in industrial sales. He graduated with a BS in engineering technology from Franklin University and has also worked as a mechanic and service coordinator. He has taken technical courses in fluid power and electronic and digital control at the Milwaukee School of Engineering and the University of Wisconsin and has served on numerous industry committees.

Leaders relevant to this article: