A company that makes all types of fireplaces and chimneys had a new press fabricated for forming top covers for chimneys. This press was built to handle all the custom designs requested by architects and builders. The tops, called chase covers, were normally made from SAE 304 stainless steel of various thicknesses.

The press was inspected as it came out of the fabrication shop. After its speed and tonnage were confirmed, it was shipped to the customer’s assembly plant to begin making chimney covers. The customer fitted it with clamping and forming fixtures and began the fine tuning process of making good parts.

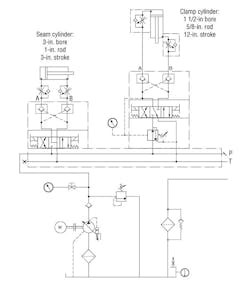

A problem showed up that wasn’t present when the press was inspected at the fabrication shop. The clamp cylinder would “cog” on its down (extend)stroke and slightly deform the chase cover, leaving unwanted marks on its exposed surface.

The hydraulic circuit shown was reviewed, and technicians decided to reduce the pressure reducing valve setting. It didn’t help. They then adjusted the meter-out flow control on the rod side of the cylinder. Increasing the speed helped, but marked the part even deeper. When they adjusted the clamp speed flow control to slow the cylinder down, the cogging problem increased. They could not find a happy medium adjustment between the flow and speed controls that would work.

When I first saw the circuit, I felt the meter-out flow control used with a pilot operated check should’ve prevented cogging. Any idea what we had to do to fix their

problem?

Solution to July's circuit design problemHose failure problem on a low pressure hose Answer: The problem with low pressure hose failing was cuased by the high velocity "needle like" decompression flow exiting the decompression valve outlet. The hose was attached to the valve and immediately routed into a 90° bend down the side of the press. The high-velocity decompression flow eroded the hose from the inside out and accelerated as the oil contamination increased. We bent and installed a short length of steel tube, thereby eliminating the bend in the hose. We then connected the hose without a bend running down the side of the press. This solved the problem. Eaton Aeroquip and Parker have great sections in their master hose catalogs about analyzing hose failures.

|

About the Author

Bob Sheaf

President

Robert J. Sheaf Jr., is the founder and president of CFC Insustrial Training, formerly Certified Fluid Consultants, part of CFC-Solar Inc. CFC-Solar provides technical training, consulting, and field services to any industry using fluid power technology.

Leaders relevant to this article: