Troubleshooting Challenge: Directional Valve Slams When It Shifts

Download a PDF of this article.

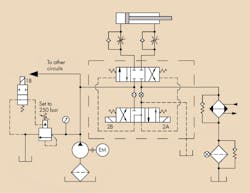

A high-speed forging press used a large vane pump to cycle four different circuits. Three of the circuits were used for setup and eject functions and the fourth, shown here, provided a secondary stamping function. A vane pump was used because the constant pounding inherent to the application can cause problems with pressure-compensated pumps. The higher cost of a pressure-compensated piston pump can be another factor.

The main directional control valve became damaged and was replaced when a new die was being installed. A spare valve with the same model number except one letter was found in the shop’s storeroom. The model number indicated the valve was configured for external pilot pressure, but the circuit called for one with an internal pilot.

Technicians removed a solid internal plug from the valve, which they figured would convert the valve to internally piloted. They installed this new valve and got the press up and running again. However, the operator said the machine didn’t sound like it did before. He felt something was making a slamming or hard thumping noise each time the new valve shifted.

What do you think the problem was, and how would you correct it?

Find the Solution

Think you know the answer to this month’s problem? Submit your solution by emailing [email protected]. All correct solutions submitted by May 1, 2017, will be entered into a random drawing for a $50 gift card. The winner will be notified, and his or her name will be printed in a future issue. Only one gift card will be awarded to any participant within a calendar year.

Solution to last Month’s Problem:

Hot Dog Machine Has Weight Problem

The main cylinder in a hot dog machine could not lift tubs fully loaded with meat. Operators noticed the hydraulic system would max out at 1,700 psi, even though the relief valve was set at 3,000 psi.

The pump/motor adapter had been mounted with its access hole pointed down, toward the base plate. This position blocked the view of the shaft coupling between the electric motor and hydraulic pump. Workers noticed that the motor’s fan was rotating, but no one thought to check if the coupling halves were, too. They assumed they were, when, in fact, the shaft key had been sheared. Installing a new key solved the problem—a part that can be had for pocket change.

About the Author

Robert Sheaf

President

Robert J. Sheaf Jr., is the founder and president of CFC Industrial Training, formerly Certified Fluid Consultants, part of CFC-Solar Inc. CFC-Solar provides technical training, consulting, and field services to any industry using fluid power technology.