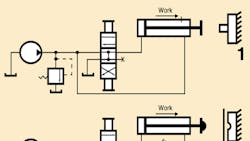

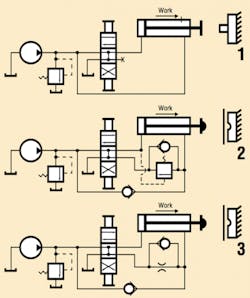

Regenerative circuits

This file type includes high resolution graphics and schematics when applicable.

Circuit 1

Rapid rod extension can be achieved by returning the flow of oil from a cylinder's head end back into its cap end. With no load, pressure in both head and cap ends is equal, so when the load is encountered, available working force depends on the differential area.

Circuit 2

Combining the rapid extension of Circuit 1 with full force in response to an applied load takes full advantage of a regenerative circuit. This circuit produces a rapid approach stroke of the piston. When the rod encounters resistance (workpiece load), pressure rises on the cap end to open the sequence valve and allow oil from the head end to flow to tank through the 4-way valve. Once this occurs, full effective force on the workpiece becomes available.

Circuit 3

This circuit provides a costly means to accomplish the same end as Circuit 2. Instead of a sequence and built-in check, an orifice and check are used. There is some backpressure remaining in the cylinder's head end because of the orifice resistance during final squeeze. But with the cylinder extended, no fluid flows across the orifice, so total available force acts on the cap end. Whether or not this circuit is appropriate for a given application depends on working force requirements.

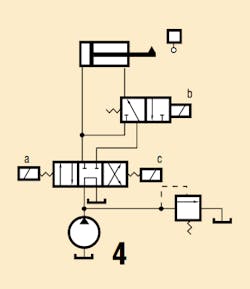

Circuit 4

When electrical control is desired, a limit or proximity switch can be used to activate and de-activate a regenerative circuit. In the circuit shown, energizing solenoids a and b extends the cylinder in a differential circuit. The limit switch de-energizes solenoid b, directing cylinder discharge fluid to tank.

This file type includes high resolution graphics and schematics when applicable.