Hydraulic guillotine removes cattle horns

In beef-processing plants, the animal's horns are cut off the head so the hide — already separated from the carcass — can be pulled over the head to remove it with less difficulty. With the horns out of the way, there also is less potential for damaging the valuable hide. (Removed horns are ground into bone meal, a byproduct used to make fertilizer.)

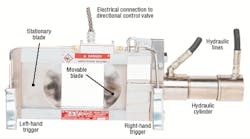

The Model 50G hydraulic guillotine dehorner from Jarvis Products Corp., Middletown, Conn., does this job in seconds. An operator simply places the central opening in the dehorner over the carcass' skull, then simultaneously depresses dual right-and left-hand triggers. The dehorner's hydraulic cylinder extends to drive a movable blade against a stationary blade, quickly cutting off the horns close to the skull. When both triggers are released, the cylinder retracts. The blades open and the operator can remove the dehorner.

Triggers can be specified to produce either electrical or pneumatic output signals. The two signals from the triggers become inputs to Jarvis' control circuit board. When two input signals reach the circuit board within half a second, the board passes an electrical output signal to solenoid coils on directional control valves at the system's power unit. The valves shift, and the 2½-in cylinder strokes, developing 9900 lb of cutting force. If only one trigger is depressed, the blade remains stationary. Likewise, should an operator contrive a way to hold both triggers depressed, the circuit board does not respond.

Jarvis Products offers a choice of three power units to support the dehorner: a 10-hp pump for electrical triggers; a 10-hp pump for pneumatic triggers; and a 5-hp pump for slower moving production lines. All run on 230/460-V, 3-phase, 60-Hz power and all develop the same cutting force at the blade.

Jarvis also offers a balancer to help operators manipulate the robust 65-lb unit. The virtually allstainless-steel construction of the 50G meets national and international requirements for hygiene, while minimizing corrosion problems at the same time. The two-trigger, anti-tie-down operating system meets necessary safety requirements.