Troubleshooting Challenge: Oil Rig has Overheating Problem

A land-based oil rig has a hydraulic power unit (HPU) that supplies 35 gpm to a lift cylinder. When the cylinder reaches full extension, the HPU’s pressure-compensated pump strokes to minimal displacement to maintain cylinder force on the superstructure for hours at a time. As originally installed, the hydraulic system would overheat when held at 3,000 psi for more than an hour. An original design goal was to reduce the HPU’s weight, so a relatively small reservoir was specified to reduce the amount of fluid in the system, and a fan-driven air-to-oil heat exchanger was provided to compensate for the smaller heat-transfer area of the reservoir.

After reviewing the original design, we determined that the problem was the case drain from the pump was going directly back to tank instead of being routed through the main heat exchanger. This meant the case-drain flow circulated in a loop without the benefit of cooling.

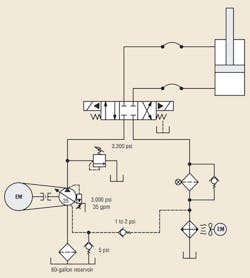

We advised the crew to install a tee in the drain line, with a 5-psi check valve between the tee and the reservoir, and a ½-psi check valve between the tee and heat exchanger. The circuit is shown in the illustration. This change routed the pump’s case drain through the heat exchanger when there was no flow in the main system.

This setup worked well for about 6 months, when an accident made it necessary to replace the pump–motor assembly. The crew installed a different brand of pressure-compensated pump and reinstalled the check-valve system on the drain line. The check valves were reused, and the pump-motor produced maximum flow only ½ gpm more than the original unit. It should have worked fine, but the overheating problem again reared its head.

Any idea what could be causing the overheating problem?

Find the solutionThink you know the answer? Submit solutions by e-mail to [email protected]. All correct solutions will be entered for a chance at a $50 gift card, and we will randomly select a winner from all correct submissions. Troubleshooting Challenge was not published in the October 2013 issue. Click here to view September's Challenge and solution: ABS Testing Setup Needed Low Pressure. |

Solution to Oil Rig has Overheating Problem:

The first thing everyone suggested was to check the safety relief valve. They lowered the relief until they heard and felt the valve relieving. They then increased the valve's pressure setting until the noise and vibration settled down. The heating problem persisted. They then replaced the heat exchanger to no avail.

They called their local hydraulic distributor, and the technician simply asked them if the return line from the 5-psi check valve going back to the tank was hot. It was. They determined that the contractor who put the new pump in had installed the ½-psi check in backwards, causing the original overheating problem since the case drain flowed directly to tank.

Congratulations to Richard McAfee, CFPE, at Texas Hydraulics, whose name was chosen at random from those who correctly answered November's Troubleshooting Challenge. A $50 gift card is in the mail to him.

About the Author

Robert Sheaf

President

Robert J. Sheaf Jr., is the founder and president of CFC Industrial Training, formerly Certified Fluid Consultants, part of CFC-Solar Inc. CFC-Solar provides technical training, consulting, and field services to any industry using fluid power technology.

Leaders relevant to this article: